Heat Exchangers

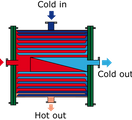

Spiral Heat Exchangers - Liquid Applications

- Normally used in Heat Recovery – Heating – Cooling.

- Self-cleaning effect due to turbulence

- High heat transfer value (K value) which leads to huge savings in energy costs.

- Compact and Robust – Nexson spiral plate heat exchanger can replace 3 traditional Shell & Tubes products – Alternative to the shell & tube exchangers

- Low maintenance cost

- For fouling duties – Can handle fouling liquids on both warm and cold sides at the same time

- Single channel heat exchanger

- Easy access for cleaning

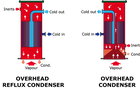

Spiral Heat Exchanger - 2 Phase Applications - Spiral Condenser

- Normally used as Vacuum Condenser – Overhead Condenser – Reflux Condenser – Vent Condenser – Gas Cooler – Steam Heater.

- High heat transfer value (K value) which leads to huge savings in energy costs.

- Minimal maintenance cost.

- Low pressure drop – down to 0,1 kPa.

- Working conditions under vacuum.

- Can be column mounted.

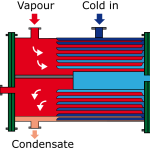

Spiral Heat Exchanger - 2 Phase Applications - Steam Heater

- Normally used as Steam / Slurry Heater – Gas Cooler – Steam Heater.

- High heat transfer value (K value) which leads to huge savings in energy costs.

- Designed to handle cyclic duties with pressure and temperature fluctuations.

- For fouling duties – Can handle fouling liquids and be opened for cleaning from time to time.

- Minimal maintenance cost.

- Low pressure drop.

Spiral Heat Exchanger - Sludge Heat Exchanger - Biogas Digestion - Energy Recovery

- Normally used as Anaerobic Sludge Heater – Raw Sludge / Digested Sludge Economizer – Pasteurizer – Effluent Energy Recovery.

- High heat transfer value (K value) which leads to big savings in energy costs.

- Self-cleaning effect due to turbulence.

- For fouling duties – Can handle fouling liquids on both warm and cold sides at the same time.

- Low maintenance cost.

- Low pressure drop.

- Easy access for cleaning.

Welded Plate Heat Exchangers - Green Box

- Normally used in Heat Recovery – Evaporation – Condensation – Reboiling.

- Square corrugated plates – high turbulence – welded together.

- The most robust heat exchanger of its category – patented soft corner design.

- High heat transfer value (K value) which leads to huge savings in energy costs.

- Compact and Robust – Nexsons Green Box heat exchanger can replace 5 traditional Shell & Tubes products.

- Minimal maintenance cost.

- For semi fouling media – Can handle fouling liquids on both warm and cold sides at the same time for single phase applications.

About NEXSON Group:

NEXSON GROUP IS LOCATED IN BURGUNDY, IN THE CENTER OF FRANCE.

Rich with 30 years of experience in the design and manufacturing of welded heat exchangers, pressure vessels and filters Nexson Group covers a large range of processes and applications such as Refinery, Oil & Gas, Petrochemicals, Coke Oven, Gas & Steel, etc. always supporting our customers to maximize heat transfer and heat recovery.

LONG TERM EXPERIENCE IN PROCESS

Emphasized skills in all product activities, areas of expertise in many different processes and successful accomplishments in industry, this is what Nexson and his people can bring you.

INNOVATION AND YOU

By permanently listening to the customers’ and market needs Nexson Group has made of Research and Development its top priority. Constant investments in machinery allow Nexson Group to offer you every time a better quality to the market.

WE ACCOMPANY YOU AT EACH STAGE OF YOUR PROJECT

We do not just supply heat exchangers. We have experts in many processes to help you optimize the manufacturing process. We also act as a focal point when it comes to restoration, reconditioning and thermal resizing of an existing heat exchanger.

PERFORMANCE AND VALUES

OUR CAPACITY OF INNOVATION IS YOUR PERFORMANCE INDICATOR. LET’S CREATE NEW VALUE TOGETHER!

Because they have the capacity to commit, create, innovate and act, our people -regardless of their level or their status- are the essential levers of performance to best meet your expectations by offering consulting advice, quality and advanced expertise.

REACTIVITY AND FLEXIBILITY OF AN INDEPENDENT COMPANY

Largely autonomous and backed by a solid financial structure, Nexson can look forward to the long-term future as an independent company standing out as an innovative and exemplary player in heat exchangers development.

The motivation, experience and skills of Nexson team largely contribute to professional support in your everyday projects.

RELIABLE DELIVERY TIME

Delivery accuracy is one of the major monitored quality/production points we focus on. Leadtime compliance is our motivation!

EXPERT AUTHORITY, KNOW-HOW AND MOTIVATION

Our performance is the result of the commitment of all employees. From the engineer to the maintenance technician and the production companion, everyone has a keen sense of adaptation, responsiveness and professionalism. They were able to take up the different challenges they faced during major global contracts.

RELIABLE QUALITY OF OUR PRODUCTS AIMING AT A CONTINUOUS CUSTOMER SATISFACTION

Our ISO9001 v2015 certified French production guarantees permanent customer satisfaction. It complies with standards such as ASME, GOST, PED, U-STAMP, API 664, etc.…

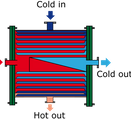

SPIRAL PLATE HEAT EXCHANGER

Thanks to its thermal efficiency, its strength and its versatile design, the Spiral Plate Heat Exchanger has proven since 1930 to be essential in fields as various as Refineries, Petrochemical, Oil&Gas or Environment…

Able to work in extreme conditions (of pressure and temperature), this single-channel heat exchanger, with a self-cleaning effect, has become the alternative to the shell & tube exchangers.

Nexson Group designs, develops and manufactures your spiral heat exchanger in the formable and weldable materials of your choice (GreenSpiralTM ). More compact and 3 times more thermally efficient than tubular heat exchangers, this Spiral heat exchanger provides substantial savings in installation, operation and maintenance.

Our Spiral Plate Heat Exchangers are made of 2 concentric channels on which spacer pins are welded to form the channel’s gaps. Each channel gap and the width of the channels are selected to meet each Customer’s specific requirement and working conditions. It permits to take into account the flow rates, the sizes of the particles for fouling fluids and the pressure drops. These spacer pins facilitate turbulent flow in each channel.

- Single-channel

The single-channel flow of our heat exchangers makes it a unique feature in the world. - Self-cleaning effect

Thanks to the single-channel configuration, a turbulent flow is created to handle tough medias.

As it is a single channel heat exchanger, if there is any cross-section reduction inside the channel, flow velocity will increase flushing out the deposit. - Fouling duties

Originally the spiral plate heat exchanger was mainly used in the pulp and paper industry where fouling problems were frequent when using classical shell and tube exchangers (or multi-channels heat exchangers) due to fibers in the effluents. - Tough process conditions

Because of their robust construction Nexson spiral heat exchangers are meant to handle cycling duties. Nexson spiral heat exchangers can expand without mechanical failure when pressured or by an increase in temperature.

Spiral plate heat exchangers can be manufactured in any material that can be formed and welded (carbon steels, stainless steels, duplex, super duplex, titanium, nickel alloys, etc…) – SA 516 Gr60, SA 516 Gr70, 304 / 304L, 316 / 316L, UNS S310803, UNS S32205, UNS S32750, 904L, 254 SMO, C276, C22, C2000, Titanium…

Nexson spiral heat exchangers are used for a design pressure from full vacuum to 80 barg and at -200°C design temperature to 450°C.

Nexson Group supplies a wide range of spiral heat exchangers from customized to standard units.

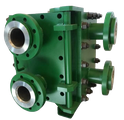

WELDED PLATE HEAT EXCHANGER

Remarkable efficiency, unique design and compactness

GreenBoxTM is a fully welded heat exchanger, made of square corrugated plates welded together, forming the heart of the heat exchanger. There is no gasket between the plates; the waterproofness is done by a weld. Only the removable side panels have gaskets for external sealing.

The heart of the heat exchanger GreenBox is accessible for inspection or cleaning by simply removing the 4 side panels.

The patented soft corners design, (the heart/panels assembly of the GreenBox), makes this heat exchanger the most robust of its category and is the ideal solution for operation in tough process duties with high pressures and temperatures.

Greenbox is a concentrate of thermal efficiency as heat recovery interchanger, condenser, reboiler or evaporator, and can be used in fouling duties.

High turbulent flow induced by the corrugated plates of GreenBox makes it about 5 times more thermally efficient than a traditional shell & tube heat exchanger. It also allows a temperature approach of 2°C.

A better heat transfer coefficient means also the compact size of Greenbox and this can also reduce significantly installation, operation and maintenance costs.

Ingenious corner’s design brings mechanical reliability to the GreenBox heat exchanger.

The GreenBox works in simple or multi-pass and, if needed, the access to the plates for inspections and cleaning is given by simply removing the side panels.

GreenBox Welded Heat Exchangers can be manufactured in any material that can be formed and welded such as 304 / 304L, 316 / 316L, 904L, 254 SMO, C276, C22, C2000, Titanium…

Nexson GreenBox is used for a design pressure from full vacuum to 50 barg, from -50°C design temperature to 450°C.