Tank Mixing Systems

Eductors

Liquid jet mixing nozzles, Eductors, and tank mixing systems

Körting liquid jet mixing nozzles, eductors, are the main components of special mixing systems which can be applied for continuous as well as discontinuous mixing duties. They can be used as complete replacement for mechanical agitators and in many cases they surpass their mixing results.

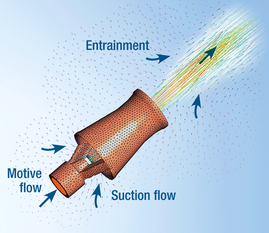

Working principle

A liquid flow is taken from the tank and supplied to the liquid jet mixing nozzles, eductors, via a motive pump. Inside the motive nozzle pressure energy is converted into kinetic energy. Negative pressure is generated at the motive nozzle outlet and the ambient liquid is sucked in. The suction flow is strongly intermixed with the motive flow in the adjoining mixing section and accelerated by impulse exchange. The drag effect of the exiting mixed flow increases the mixing effect.

Advantages of Körting mixing nozzles / eductors

- complete mixing of the tank content

- low investment costs

- wear-resistant, long service life – no moving parts inside the tank

- no sealing problems – no shaft ducts

- no dead zones

- no maintenance in the tank

- low energy input

Mixing nozzles, eductors, are customized and designed for every application

Fields of application

- mixing storage tanks, fuel oil tanks, wastewater treatment tanks, neutralization tanks, reactors, food storage tanks, stormwater tanks and others

- complete homogenization of different liquids

- preventing settlements and sedimentation

- avoiding the formation of different temperature layers

- as discharge support

- for waste water treatment applications (ejectors in SBR-Plants operated with compressed air)

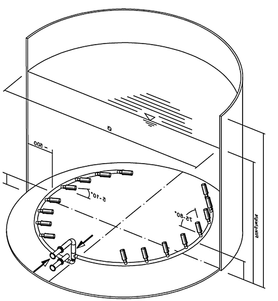

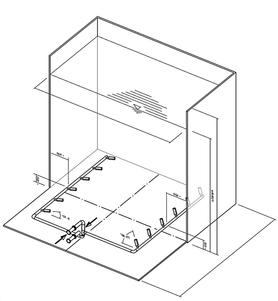

Structure and function of tank mixing systems - Eductors

The aim of Körting Hannover GmbH is to design customised tank mixing system solutions for each specific tank. The purpose of the tank mixing system is to generate a liquid circulation of the whole liquid volume which leads to complete mixing and prevents sedimentation. A guided directional flow will be generated by the mixing system. Therefore, flow velocities occur, which are higher than the sinking velocities of the particles in the liquid, so that settlement is avoided. The two examples in the figures on the right illustrate the principle of tank mixing systems:

The specific number of liquid jet mixing nozzles,eductors, resulting from the tank mixing system dimensioning will be placed on two pipes close to the tank bottom and the tank wall. These two pipes follow the shape of the tank. For a round tank, the pipes are semicircular whereas for a rectangular tank the pipes are straight. The required motive flow is supplied to the liquid jet mixing nozzles, eductors, via these pipes. The motive flow pipes are situated oppositely to each other on two sides of the tank. With fixtures, the pipes will be fixed above the tank bottom and at a certain distance from the tank wall. Pipe dimensioning will be according to normal flow velocities in order to keep the friction losses inside the pipes low. The size of each mixing nozzle, its alignment, e.g. the installation angle as well as the distance from one nozzle to another, are further results of the dimensioning.

One nozzle, eductor, row will point alongside the tank bottom to generate the necessary flow velocities alongside this area. At the opposite side of the tank, the second nozzle, eductor, row points upwards which generates an upward flow alongside the tank wall. By means of this guided directional flows, the whole liquid volume is moved. In order to save energy at low filling levels the nozzle, eductor, row pointing upwards can be switched off.

Dependent on the properties of the liquid to be mixed every different nozzle size has a certain range with regard to the liquid to be moved. For very large tanks it may be necessary to place a third nozzle row in the middle of the tank bottom in order to generate the required flow velocities to cover the whole distance. In the case of very high tanks, the nozzle,eductor, row pointing upwards may be positioned higher above the tank bottom to achieve optimum mixing of the whole liquid.

With the options of choosing different nozzle sizes, adjustment of nozzle, eductor, rows according to the tank shape, modification of the nozzle distances and of being flexible concerning the operation of the different nozzle rows Körting Hannover GmbH is able to dimension the optimum tailor-made tank mixing solution for every specific purpose. E.g. for full homogenization, for prevention of settlements, for prevention from different temperature layers or for a complete mixture of different liquids.