Jet Ejectors, Steam Jet Heaters, Thermocompressors

Jet Ejectors

Jet pump, ejector, motive media pump, injector – many names, same design and working principle.

A jet ejector works without a mechanical drive and therefore offers high reliability in continuous operation mode. Körting jet pumps and ejectors enjoy a reputation of being particularly straightforward and robust in their functioning as well as being low in maintenance and wear. They are designed in a multitude of materials and optimised for their application purposes. The pumping effect is generated by means of a liquid or gaseous motive medium acting as energy carrier. The application field determines the shape of the flow cross-section which is designed individually dependent on the motive medium.

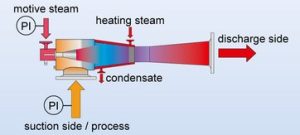

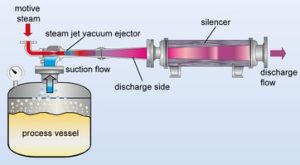

Vacuum ejectors

Steam jet vacuum ejectors remove gases and/or vapours from process operations thereby generating a vacuum in the reactor. The suction flow is compressed to a higher pressure.

General Applications

- start-up evacuation of tanks and reactors

component part of multi-stage vacuum units

Edible oil production

-

sucking and compressing hexane/vapour mixtures in the extraction plant

Jet Compressors

Steam jet compressors are part of many process engineering applications. Using them reduces the energy consumption of the process and cuts the machinery’s operational costs sustainably. Also known as thermocompressors or vapour compressors, steam jet compressors compress steam flows in various processes in a straightforward way.

Advantages

Körting steam jet compressors offer an entire range of benefits:

- low steam consumption

- long service lives

- the motive steam flow can be controlled by valve or nozzle needle.

- there are no movable parts in contrast to mechanical compressors.

- little maintenance is required.

- exceptional reliability

- quick to adapt to new operating conditions.

- high-quality manufacturing

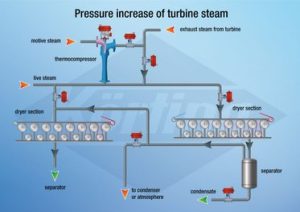

Thermocompressors

High-pressure steam is released in a motive nozzle to bring it up to the maximum velocity. At the same time, the pressure on the nozzle’s outlet drops so that the steam that requires compressing is suctioned in. When the two flows are combined in the mixing element downstream, some of the motive flow’s kinetic energy transfers to the suction flow. The mixed flow is then slowed down in the subsequent diffuser and an increase in pressure occurs at the same time. This steam mixture can be used again in the process afterwards at the higher-pressure level.

Controllable Nozzle Needle

To expand the operating range, Körting thermocompressors come as controllable versions with adjustable nozzle needles. Therefore, it’s possible to change the motive steam flow without having an impact on the motive pressure. In the part load range, this sometimes means huge advantages in terms of motive steam consumption compared with a solution requiring an external reduction in the motive pressure using a separate control valve.

Applications

- Increase the pressure of low-pressure steam networks.

- Evaporation

- Pulp Digestors

- Pulp Driers

- Paper machines

- Single cylinder

- Multi-cylinder

- Flash stem for steam boxes

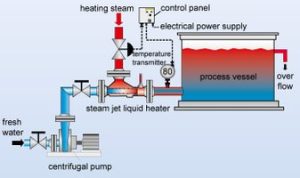

Steam jet heaters

The condensation of steam is probably the most commonly used method of producing hot water. Mixing water with steam makes this process extremely flexible; depending on the mixing ratio the temperature of the water can be selected within a wide range.

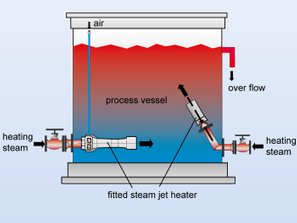

Fitted steam jet heater

These heaters are to be installed in a liquid tank. Steam flowing through the nozzle is expanded to produce low pressure at the outlet. This causes the neighbouring liquid to be sucked in. Steam condenses thereby heating the liquid which, when flowing out of the heater, achieves a further intermixing action in the tank.

Steam jet flow heater

To be installed in piping systems. Liquid flows through the heater and steam is pressed into this liquid through the bore-hole of a condensation nozzle. The condensing steam then effects a direct heating of the liquid.

Applications

Chemical industry, Food industry, Paper industry

Heating of liquids or also liquids/solids mixtures.

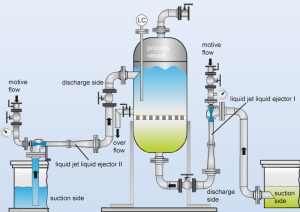

Liquid jet liquid ejector

A liquid motive medium is used to suck off another liquid and to convey it to a higher pressure. High turbulence achieves a homogeneous intermixture of both flows.

Applications

Ship-building

- Inside the ship: pumping and cargo out bilges, chain lockers, holds ballast tanks

Water treatment

- dilution of lyes and acids

Food- and chemical industry

- pumping and mixing of diverse liquids

Synthetic fertilizer plants (UREA plants)

- pumping “carbamate”-solution back to the Urea-reactor

Hydroelectric power stations

- emergency drainage of pump pits

Sea-water evaporators

- conveying concentrated sea-water (brine)

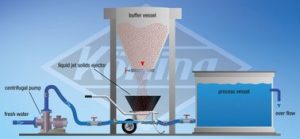

Liquid jet solids ejector

Bulk material conveyor technique (bulk handling) with Körting ejectors.

A liquid motive medium is used to convey solids. The solids are either introduced via a funnel or they can also be sucked in. A carrier medium e.g. water or air is mixed in to improve the delivery effect.

Applications

Water treatment and water works.

- conveying filter materials such as activated carbon, gravel, exchange resins

- conveying lignite dust in activated sludge

Swimming pool/pool construction and building

- as an elevator (water jet ejector) for conveying solid filter material

Ship-building

- pumping water/solids mixtures out of the deep.

- laying of marine cables.

- conveying ash/air mixtures from incineration systems on passenger ships.

Special solutions for larger delivery volume

For larger quantities and grain sizes of more than 8 mm, special solutions can be used. Depending on the area of application, liquid jet solid ejectors are designed as welding or welding/casting construction for optimally individual applications.