Spiral Heat Exchangers

Spiral Heat Exchangers - Liquid Applications

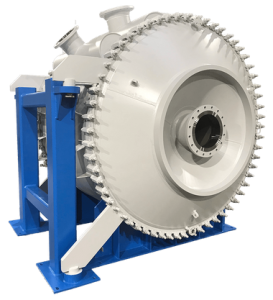

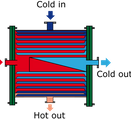

Spiral Plate Heat Exchangers are made of 2 concentric channels on which spacer pins are welded to form the channel’s gaps. Each channel gap and the width of the channels are selected to meet each Customer’s specific requirement and working conditions. Correct design takes into account the flow rates, viscosities, sizes and concentration of particles for fouling fluids and pressure drops etc.. These spacer pins facilitate turbulent flow in each channel.

Advantages:

- Single channel

The single channel flow makes gives Spiral Heat Exchangers a unique design feature for even heat transfer distribution and a high heat transfer value (K value). Compact Size and Robustness

In liquid-to-liquid duty, one Nexson spiral heat exchanger can replace 3 traditional Shell & tubes products, thus liberating footprint for other process equipment.

- Self-cleaning effect – No Dead Zones

Thanks to the single-channel configuration, a turbulent flow is created to handle tough and fouling media on one or even both sides.

As it is a single-channel design, if there is any cross-section reduction inside the channel, flow velocity will increase thus increasing turbulence flushing out the deposit. Low Maintenace Cost

The self-cleaning effect provides for less frequent stops for cleaning and maintenance, and necessary spare parts are a minimum due to the unique design, thus necessary operation and maintenance costs are exceptionally low.

Full access to the heattransfer area

Access and inspection of the whole heat transfer surface is possible thanks to openable end covers.

- Fouling duties

Originally these spiral plate heat exchangers were used in the pulp and paper industry where fouling problems are frequent when using classical shell and tube exchangers (or multi-channel heat exchangers) due to fibers or particles in the media. - Tough process conditions

Because of their robust construction Nexson spiral heat exchangers can handle high temperatures and/or pressure even in cycling duties. Nexson spiral heat exchangers can handle material extension without mechanical failure when pressurized or by changes in temperature. Small Temperature Approach Possible

Nexson spiral heat exchangers provide the possibility of media temperature approach around 3°C.

Alternative to conventional Shell and Tube heat exchangers

Thanks to its thermal efficiency, robustness and its versatile design, the Spiral Plate Heat Exchanger has proven, since the 1930ies, to be essential in fields and industries as various as Pulp and Paper, Refineries, Petrochemicals, Oil&Gas, Food Industries, Mining, Steel and Metal manufacturing as well as Environmental Applications as Biogas production and Waste Water Treatment, etc.

Nexson Group designs develops and manufactures your spiral heat exchanger in the formable and weldable materials of your choice (GreenSpiralTM). More compact and 3 times more thermally efficient than tubular heat exchangers, these Spiral heat exchangers provide substantial savings in installation footprint, as well as operation and maintenance costs.

Thanks to its specific design, the liquid-to-liquid heat exchanger can handle one or two fouling fluids. Both channels are easy to access for inspection and cleaning.

Able to work in extreme conditions (of pressure and temperature), this single-channel heat exchanger, with a self-cleaning effect, has become the alternative to the shell & tube exchangers.

Traditionally uses for

Spiral heat exchangers for liquid-to-liquid applications are used in most industries: – Pulp and Paper, Refineries; – Petrochemicals; – Oil&Gas; – Food Industries; – Mining; – Steel and Metal manufacturing, as well as,

Environmental Applications as: – Biogas production; and Waste Water Treatment; etc. in applications for:

- Heat Recovery

- Heating

- Cooling

Material Selection and Design Limits

Spiral plate heat exchangers can be manufactured in any material that can be formed and welded (carbon steels, stainless steels, duplex, super-duplex, titanium, nickel alloys, etc…) – SA 516 Gr60, SA 516 Gr70, 304 / 304L, 316 / 316L, UNS S310803, UNS S32205, UNS S32750, 904L, 254 SMO, C276, C22, C2000, Titanium…

Nexson spiral heat exchangers are used for a design pressure from full vacuum to 80 barg and at -200°C design temperature to 450°C.

Nexson can provide the biggest Spiral Heat Exchangers in the world, with up to 500 m2 surface area or up to 4 m in diameter.

Nexson Group supplies a wide range of spiral heat exchangers from customized design to standard units.

Spiral Heat Exchanger - Sludge Heat Exchanger - Biogas Digestion - Energy Recovery

- Normally used as Anaerobic Sludge Heater – Raw Sludge / Digested Sludge Economizer – Pasteurizer – Effluent Energy Recovery

- High heat transfer value (K value) which leads to big savings in energy costs

- Self-cleaning effect due to turbulence

- For fouling duties – Can handle fouling liquids on both warm and cold sides at the same time

- Low maintenance cost

- Low pressure drop

- Easy access for cleaning

Spiral Heat Exchangers - Bi-Phasic Applications

Spiral Plate Heat Exchangers are made of 2 concentric channels on which spacer pins are welded to form the channel’s gaps. Each channel gap and the width of the channels are selected to meet each Customer’s specific requirement and working conditions. Correct design takes into account the flow rates, viscosities, sizes and concentration of particles for fouling fluids and pressure drops etc.. These spacer pins facilitate turbulent flow in each channel.

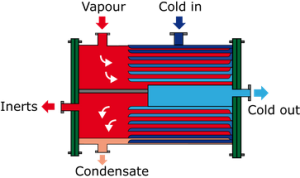

CONDENSATION

The vapor circulates, cross flow, in a fully opened channel, with negligible pressure drop and the coolant circulates in a closed spiral channel.

Thanks to its versatile design, it can be directly installed on the top of acolumn/rector without any supporting system, reducing quite much installation costs.

It is perfectly suitable for vacuum condensation with negligible pressure drop. It can be used as vent condenser.

EVAPORATION

The fluid to evaporate circulates in an adjusted channel gap, fully opened, that allows working with fouling fluids. It also allows easy access for an inspection or an eventual mechanical cleaning.

NEGLIGIBLE PRESSURE DROP

Thanks to the cross flow on the steam / vapour side there is nearly no pressure drop (we are in a range of 0.1 kpa)

CONDENSATION UNDER VACUUM

With a very low pressure drop, this allows spiral heat exchangers to process under complete vacuum conditions.

SUB-COOLING OF INERTS AND/OR CONDENSATES

We can set up different mechanical constructions to subcool (or not) inerts and condensates

COLUMN MOUNTED

Spiral heat exchangers can be directly mounted at the top of the distillation column / reactor without any supporting system

STEAM HEATER

Spiral heat exchanger is made to handle cycling duties, thanks to its robust construction. Nexson spiral heat exchanger can expand without mechanical failure during the pressure and/or temperature increase.

LOW MAINTENANCE COST

Nexson spiral heat exchangers are designed to maximize heat transfer surface. They can be set up vertically or horizontally with no need for complex installation. In addition maintenance costs are very low.

HEAT TRANSFER AREA SURFACE

Heat transfer area available from 2 to 3000m².

Traditionally uses for

Spiral heat exchangers for Bi-Phasic applications are used in most industries: – Pulp and Paper, Refineries; – Petrochemicals; – Oil&Gas; – Food Industries; – Mining; – Steel and Metal manufacturing, in applications as:

- Vacuum Condenser

- Overhead Condenser

- Reflux Condenser

- Vent Condenser

- Gas Cooler

- Steam Heater

Material Selection and Design Limits

Spiral plate heat exchangers can be manufactured in any material that can be formed and welded (carbon steels, stainless steels, duplex, super-duplex, titanium, nickel alloys, etc…) – SA 516 Gr60, SA 516 Gr70, 304 / 304L, 316 / 316L, UNS S310803, UNS S32205, UNS S32750, 904L, 254 SMO, C276, C22, C2000, Titanium…

Nexson spiral heat exchangers are used for a design pressure from full vacuum to 80 barg and at -200°C design temperature to 450°C.

Nexson can provide the biggest Spiral Heat Exchangers in the world, with Heat transfer area available from 2 to 3000m². and up to 4 m in diameter.

Steam Heaters - Bi-Phasic Applications

STEAM HEATER

The Spiral Heat Exchanger model 3 can be used as steam heater for tough duties. Fouling duty channel with opeanable cover enables easy access for inspection or for an eventual mechanical cleaning

Spiral heat exchanger are made to handle cycling duties, thanks to its robust construction. Nexson spiral heat exchanger allows material expansion without mechanical failure during pressure and/or temperature increase. This why spiral heat exchanger are used as steam heaters.

CONDENSATION

The vapor circulates, cross flow, in an alternated channel, with negligible pressure drop and the coolant circulates in an accessible spiral channel.

NEGLIGIBLE PRESSURE DROP

Thanks to the cross flow feature for the steam/vapour side there is nearly no pressure drop.

LOW MAINTENANCE COST

Nexson spiral heat exchangers are designed to maximize heat transfer surface. They can be set up vertically or horizontally with no need for complex installation. In addition, maintenance costs are limited.

HEAT TRANSFER AREA SURFACE

Heat transfer area available from 2 to 500m².

Spiral heat exchangers in Industry

Spiral heat exchangers are used in many different industrial applications due to their efficient and reliable heat transfer capabilities for challenging media. Their flexibility and ability to handle different liquids, dirty/fouling or high viscous media or product slurries with high solid content, as well as gases or bi-phasic media make them useful in many fields and applications. The spiral heat exchangers are often used as economizers, heaters/coolers, or in two-phase applications such as condensing or evaporation operations, steam heaters, reboilers, etc.

Below are some Industries and applications where Spiral Heat Exchangers can be applied with great success:

Oil & Gas Industry:

In the Oil & Gas industry, Onshore and Offshore, several Heat Exchanger positions can be handled efficiently by Spiral Heat Exchangers.

One such application is for MEG Reclamation:

MEG (Mono-Ethylene Glycol) is widely used in wellheads and pipelines to prevent hydrate formation in pipelines. The goal of MEG reclamation process is to put a MEG-water-salt mix in contact with a heated recycled stream of MEG to recover the MEG and water components. The Spiral heat exchangers have been, for a long time, proven to be the ideal heat exchanger to handle difficult operating conditions and simplify drastically maintenance frequency. Nexson spiral heat exchangers are used for mono-ethylene glycol recovery loops thanks to their ability to handle particles without any crystallization.

Petroleum Refineries:

In Petroleum Refineries petroleum is transformed and refined into useful products such as gasoline, diesel fuel, bitumen and asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha.

Petroleum Refining, being of fossil origin has opportunities for Carbon Capture as well as blending with fossil-free fuels, BioFuels, and research for new process routes for fossil-free feedstocks, such as new bio-oils feeds and carbon capture utilization.

Refining petroleum requires several process steps such as: – Desalting; – Atmospheric and Vacuum Distillation; – Catalytic Cracking; – Reforming; – Blending, etc.

One such application is for the Coker unit as an Economizer or Cooler:

In the coker process, the goal is to convert heavy elements to lighter products and flexigas. The main advantages of this process are to create a high-value liquid product as well as clean flexigas, which can be used in different ways, either as refined fuel or for power generation.

With wide channels, compact sizes and correctly selected geometry for an optimal velocity of media streams, Spiral Heat Exchangers have successfully solved the fouling problem of heat exchange equipment in the difficult coker process.

- Spiral Heat Exchanger is used as an economizer to preheat the slurry stripper feed.

- Spiral Heat Exchangers are being used as coolers to cool the slurry stripper bottoms.

Petrochemical Industries:

An enormous amount of chemicals of various types are being made from petroleum derivates for industrial use and consumer goods that require a wide range of different unit operations. Some of the most common petrochemicals manufactured worldwide are PVC and Vinilchloride, PolyEthylen, PolyAmides, Ethylene Glycol and PolyEsters, PolyStyrene, Therphtalic Acid and PET, TDI (Toulene Diisocyante), MDI (Methylene Diphenyl Diisocyanate), etc.

Two such application is for the PVC Process – Reflux condenser and PVC Slurry Interchanger:

Nexson heat exchangers are adapted to comply with environmental constraints and high-pressure requirements. In the PVC industry, fouling due to the high concentration of suspended solids in the media and viscous polymers requires intensive maintenance when dealing with multi-channel heat exchangers. Spiral has been for a long time proven to be the ideal heat exchanger to handle difficult operating conditions and simplified drastically maintenance frequency.

Spiral Heat Exchangers can be applied with great success as:

- Reflux Condensers. The reflux condenser is mounted directly on the striping column.

- PVC Slurry Interchanger to recover heat from PVC slurries.

Mining and Steel Industries:

With the ongoing energy changes from traditional fossil-based energy and fuel to the electrification of processes and vehicles the mining industry will be affected as more minerals will be necessary for batteries etc. Global warming and new more sustainable mining and mineral upgrading processes are being developed to reduce carbon footprint. Also, for the steel industry new processes are being researched to eliminate carbon-intensive coke oven gas and reduce iron by Direct Reduction Process with H2 gas as a reduction agent.

The traditional production process, with coke oven gas, is likely to be used for many years in most parts of the world. These facilities need upgrades for better energy effectiveness, lower emissions, and have huge opportunities for Carbon Capture and carbon capture utilization.

Spiral Heat Exchangers are often used in Mineral upgrading and leaching processes for minerals as:

Zinc Slurry heating, these Spiral Heat Exchangers are customized units to heat zinc slurry with steam, while in operation always keeping the heat exchanger clean. The unit is purely symmetric, thus the end user can reverse the flow direction and media for both channels, in such a way that zinc slurry and steam change channels, when zinc fouling build-up starts to reduce thermal performances.

Spiral Heat exchangers are also widely used in the Coke Oven Gas upgrading process as:

- Primary / Final Coolers

- Krupp Koppers Process – Dephlegmator

- Benzene / Light Oil Condensers

- Oil Coolers / Heaters

Chemical Industries:

An enormous amount of chemicals or various types are being made for industrial use and consumer goods that require a wide range of different unit operations and heat transfer. Some of the most common chemicals manufactured in the world are Sulphuric Acid, Phosphoric Acid, Sodium Hydroxide, Chlorine, Chloridric Acid, Ammonia, Peroxide, Formol and Formic Acid, Inks and Pigments such as Titanium Dioxide, etc.

Many of these chemicals are produced through paths that benefit from the use of Spiral Heat Exchanges. To mention one of these Titanium Dioxide produced with Titanium Tetrachloride as an intermediary product uses Spiral Heat Exchanger for TiCl4 slurries with great success worldwide.

Pulp and Paper Industry:

As for many other Industries also the traditional Pulp and Paper Industry is looking for improvements and how to make better use of potentially valuable side products such as: – BioFuels from Tall Oil; – Methanol production; – Lignin separation from black liquor; – Turpentine; – Sulphuric Acid from off-gas; – BioGas and BioPellets; – New BioChemicals; etc. Many Pulp mills, using the Kraft (sulfate) process, are also self-sufficient in energy, export electricity to the grid and provide district heating to nearby cities. Modern Pulp Mills also have the potential for a Negative Carbon footprint with the use of Carbon Capture and Storage or Utilization. New concepts are created, and these new mills are often called BioPruduct Mills.

Spiral Heat exchangers are also widely used in Pulp and Paper Industry applications, for media such as: – White Liquor; – Black Liquor; – Green Liquor; – White Water; – High Concentrated Condensate; – Foul Condensate; etc.

Food industry:

Growing populations increase the challenges of providing raw materials, processing and transporting food to consumers. Erivac can provide process equipment for a large range of food industries, such as: – Dairy Products, milk and milk proteins; – Breweries; – Fruit Juices; – Starch and vegetable proteins; – Sugar and Alcohol industries; – Edible Oils and Fats; – Soups and Sauces etc. In many cases, Wastewater from Food Industries also has high organic loads making it ideal for BioGas Generation.

Many of these Industries have applications where Spiral Heat Exchangers are among the best options for heat transfer application due to media with high temperatures or viscosity or solid content as for Starch Slurries, Brewery Mash and Fermented media, Refining of vegetable oils at high temperatures, etc.

The spiral heat exchanger’s spiral tube design provides a compact structure and enables efficient heat transfer, making them ideal for high-efficiency heating/cooling solutions. Their ability to handle high pressures and temperatures, as well as different viscosities, dirty and fouling media, media with large content of solids, and corrosive media, makes them an important part of many industrial processes where heat transfer and temperature control are crucial.